© Jens Lehmkühler / U Bremen Research Alliance

An End to Combustion Motors: Know-How for Better Batteries

They are meant to be increasingly powerful, more durable, and lighter. The next generation of batteries already function in the lab.

However, building solid-state batteries on a larger scale so that they can reliably power cars or also airplanes is an entirely different challenge. Researchers from the U Bremen Research Alliance are working intensely on finding solutions suitable for daily life.

One could say that Dr. Julian Schwenzel was ahead of his time. When the physicist wrote his PhD on batteries 20 years ago, hardly anyone was interested in the electrochemical storage of energy. Schwenzel initially worked in plant engineering – there were few jobs for battery experts. Today, he is the head of the Department for Electrical Energy Storage at the Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM and leads a team of 22 staff members. “The team,” he says, “is growing continually. We always need more lab area, more space.”

Batteries are one of the key technologies of the energy transformation. Without high-performance energy stores, the transfer from fossil fuels to renewable energies is impossible. They are desperately needed – and not only by the automobile industry for the realization of electromobility, but also for the interim storage of surplus solar and wind power. Thus, it is a matter of immense relevance to society, in which the U Bremen Research Alliance researchers are pioneers. Due to their work, Bremen has turned into a hub for battery research in Germany.

“We share the laboratories, our competencies complement each other, And we profit from each other.”

© Jens Lehmkühler / U Bremen Research Alliance

That also has something to do with Prof. Dr. Fabio La Mantia and his research group. In the Energy Storage and Conversion Systems unit within the Faculty of Production Engineering at the University of Bremen, La Mantia holds a joint professorship, which was established in 2015 together with Fraunhofer IFAM. Both institutes – the university and Fraunhofer IFAM – are member institutes of the U Bremen Research Alliance. Whilst La Mantia carries out foundation research, Schwenzel focuses on application. Both men work closely together. “We share the laboratories, our competencies complement each other, and we profit from each other.”

How can energy and performance density be increased, how can charging ability and life span be improved, how can safety and recyclability be elevated – those are some of the questions that the research groups address. “We work in two directions,” states Schwenzel. “On the intelligent surveillance of the batteries with algorithms and also on new materials.”

© Jens Lehmkühler / U Bremen Research Alliance

The existing lithium ion batteries, like the ones that have been fitted in cars, laptops, and phones for a long time, use liquid electrolytes to conduct electric current. Their disadvantage: They are flammable and their potential has been realized. “Solid instead of liquid,” is therefore the plan. Solid materials, such as sulphides or polymers, are being tested. They are not flammable, have a high energy density, and can be processed more easily.

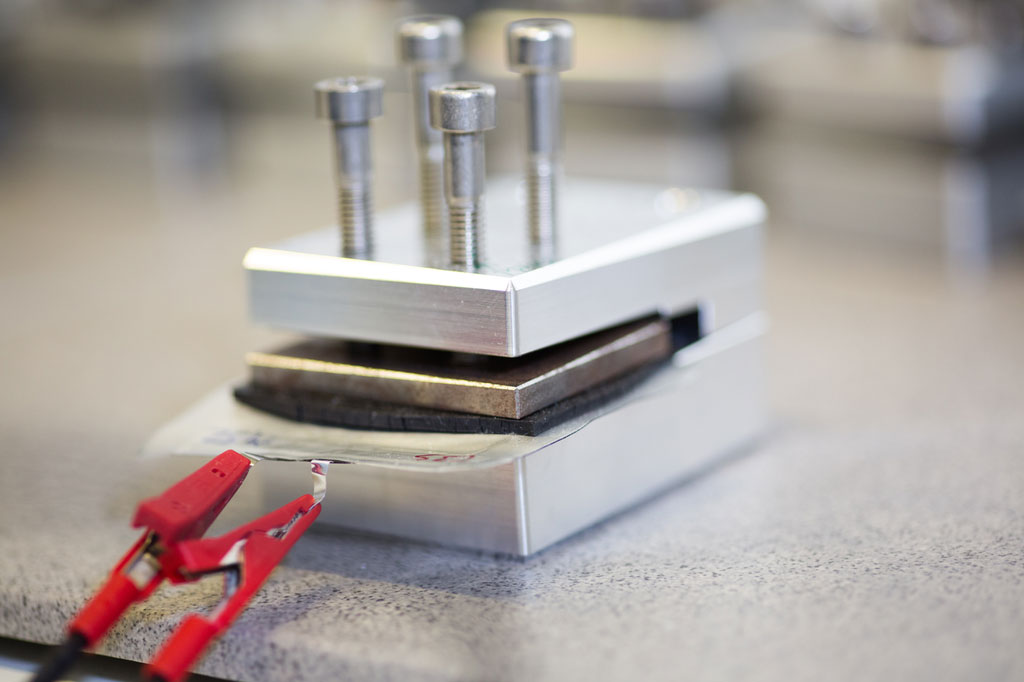

“The material classes have different characteristics,” explains Schwenzel. For example, polymers can be processed well and sulphides can be charged and discharged quicker. That is important for the automobile industry, which is one of Fraunhofer IFAM’s customers. However, sulphides are also sensitive to humidity. In the lab, the researchers have tested varying material recipes. The solid-state batteries work perfectly when they are 5 cm x 5 cm in size. However, Schwenzel states that it is a whole different task to produce them on a larger scale. “That involves several thousand layers for interconnected, multi-layer, individual batteries to make a whole battery system. No one can do that at the moment.”

“Basically, it is all about better understanding batteries and optimizing them.”

Immense know-how is required to construct electrochemical systems. “The process chain – from the powder to the battery – is complex. It is difficult to control the electrochemistry and that is something that should not be underestimated,” emphasizes Schwenzel. Batteries have a life of their own: They age, every single one is different, and small contaminations during production can have a great impact on their life span.

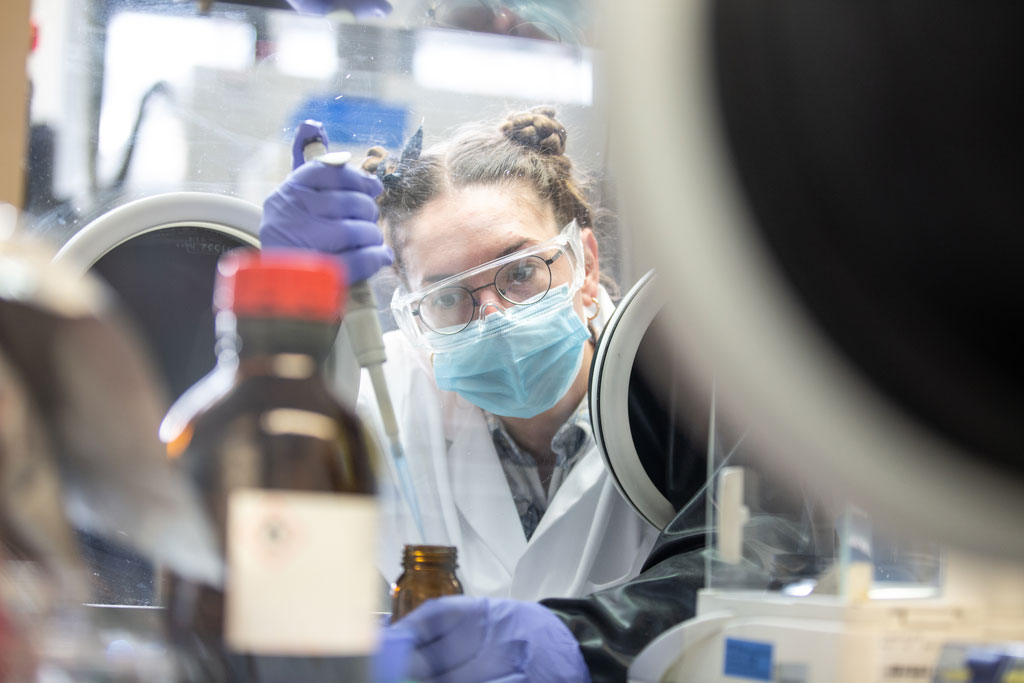

Battery analysis is one of Fabio La Mantia’s expert areas. His research group has developed a method to identify the weak spots of an operational battery and predict its life span – independently of the type of conductor. “Basically,” he says, “it is about better understanding batteries and optimizing them.” This is done by means of continually recording data. “We’re talking about a dynamic frequency analysis,” states La Mantia.

© Jens Lehmkühler / U Bremen Research Alliance

The chemical engineer, who completed his PhD at ETH Zurich and subsequently worked at Stanford University in California and at the Ruhr-Universität Bochum, came to Bremen in 2015 because of the battery research. “I was always interested in seeing the application of my work in the real world,” he says. “The conditions for that here are optimal and I enjoy solving problems.”

The Italian, whose work was honored with one of the renowned ERC Grants from the European Research Council, is focused on solving the “lithium problem.” The metal is one of the most important raw materials for batteries. The demand for lithium will skyrocket in the next years, especially due to the automobile industry. It will be in short supply and it is only mined in a few countries under difficult conditions.

“The question is: Can we find technologies that are not based on Lithium, that are more sustainable, and more cost-effective?,” asks La Mantia. Research is being carried out into zinc-based batteries that are particularly interesting for stationary applications, such as the storage of solar energy – or also into metal-air batteries.

© Jens Lehmkühler / U Bremen Research Alliance

There is another approach to the “lithium problem”: The mining of the raw material in Germany. In its natural form, lithium can be found in salts. La Mantia and his research group have found a way to extract the metal from geothermal sources and from waste water. Much like solid-state batteries, the process already works in the lab. Once more, upscaling is the challenge. “We are already in talks with companies about this,” he states. “Recycling is a big aspect fr us,” adds Schwenzel. Thus, the researchers are working on different ways to deconstruct batteries and recycle the raw materials.

“Our advantage is that we can transfer our expertise from other fields of applicationinto battery research.”

The battery sector is booming. Across the globe, scientists are working on a new generation of batteries. Schwenzel is not scared of the competition. “Our advantage is that we can transfer our expertise from other fields of application into battery research.” One interesting application is the printing of batteries. They can then take on other forms outside of the usual rectangular shape quite well. It will take some time until such technologies become part of day-to-day life. Schwenzel is reckoning with five years for solid-state batteries: “Then they could be ready to use.”

Project „NeuroBatt“

The Fraunhofer IFAM is carrying out research on an optimized operation strategy for the efficient and sustainable usage of electric energy stores. The research is being funded by the Federal Ministry for Economic Affairs and Energy (BMWi). Computer-based neural networks are implemented for the surveillance of battery conditions. They are fed with real-time measurements of the “state of health” of the batteries in operation in differing scenarios as well as the results of cyclic aging tests. This creates a comprehensive data basis for the teaching of the networks, which identify aging-relevant parameters with the help of artificial Intelligence. In this way, a prognosis tool for the prediction of battery life span is created.

This article comes from Impact – The U Bremen Research Alliance science magazine

The University of Bremen and twelve non-university research institutes financed by the federal government cooperate within the U Bremen Research Alliance. The joint work spans across four high-profile areas and thus from “the deep sea into space.” Biannually, the Impact science magazine provides an exciting insight into the effects of cooperative research in Bremen.