© Hajo König

Where There’s Stress and Aggravation

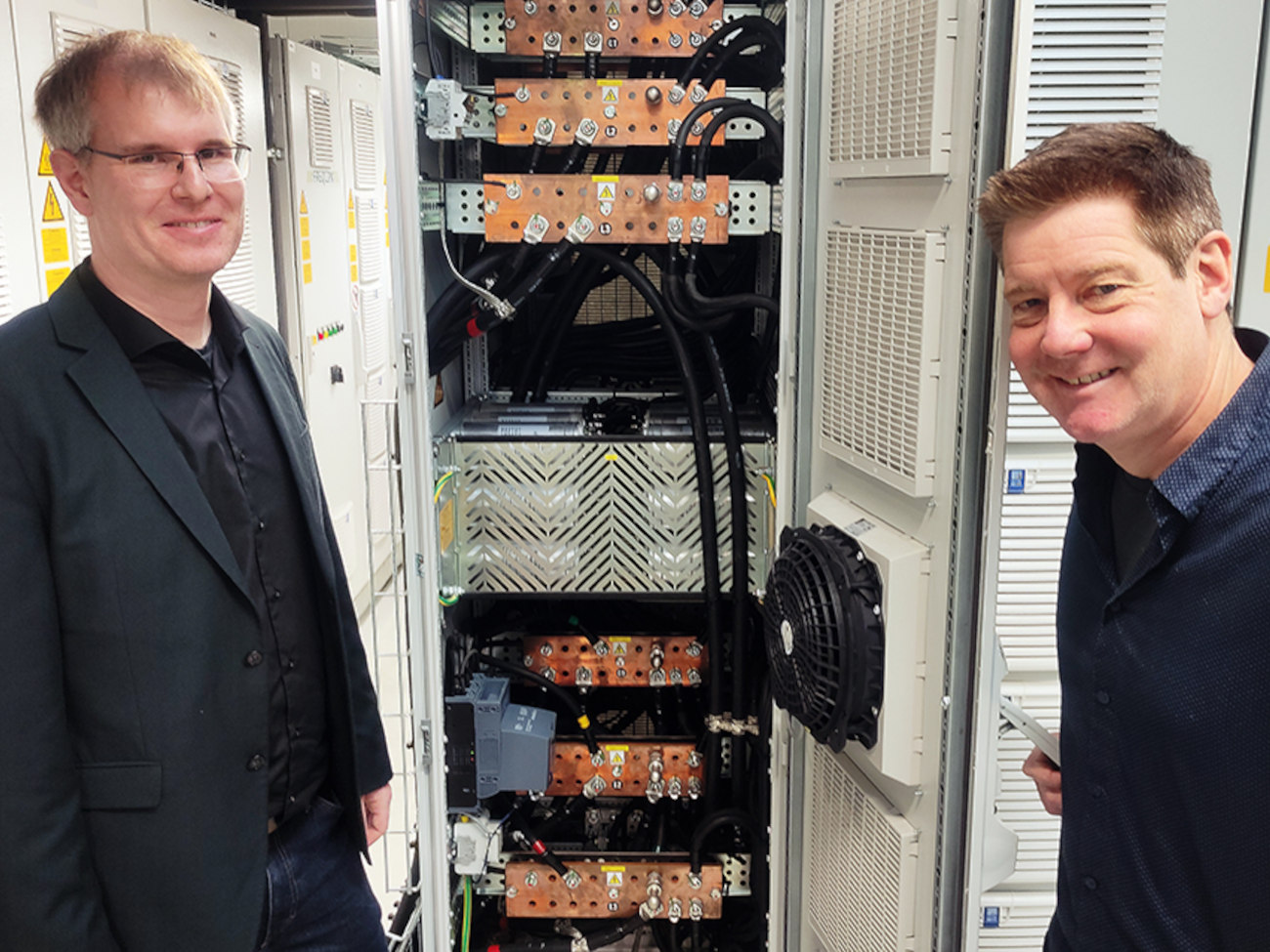

HiPE LAB: Laboratory unique to Europe puts power electronics through their paces at the University of Bremen

Wind turbines are getting increasingly bigger. The taller they are, the higher their wind yield – both on land and at sea. A height of 100 to 120 meters is already standard, and turbines up to 300 meters high are already being tested. The high-tech turbines are crammed with highly sensitive electronics that have to operate smoothly for a very long time. To ensure this, they are “stressed and aggravated” in research. One place this is done is in FZ Hall 1a near the Central Campus Building at the University of Bremen.

No protests can be heard from the tech-filled hall when the HiPE-LAB team’s tests are underway. But what engineers Wilfried Holzke and Johannes Adler do there with power electronics can make you break out into shivers or a sweat. “That’s exactly what we do in this lab. Sometimes our ‘test candidates’ have to withstand frost in extremely dry air, then again extreme heat in high humidity,” says Holzke, the Scientific Director at the HiPE-LAB. Even so, the whole operation is still noisy: the employees wouldn’t be able to cope without noise-canceling earplugs. The cooling system and the hum of the transformers make a loud noise – at least that’s what you hear when you happen to pass the hall.

It is about 20 by 35 meters in size, so it could even accommodate a medium-sized swimming pool. Hall FZ 1a, which houses the HiPE-LAB, belongs to the Institute for Electrical Drives, Power Electronics and Components – IALB (Institut für elektrische Antriebe, Leistungselektronik und Bauelemente) in the Faculty of Physics/Electrical Engineering. “Without a doubt, this laboratory still impresses me every day and is one of the largest at the University of Bremen,” says Holzke. He is responsible for the “marketing” of the test laboratory – because the university also wants to and is required to earn money from it in the future.

Starting out with the HiPE-WiND Multi-Million-Euro Program

11.5 million euros: This is how much the HiPE-WiND research project was worth to the German Federal Ministry for Economic Affairs and Energy in 2017, in order to answer two fundamental questions: What is the service life of power electronics in wind turbines? Which environmental and load conditions play a role in the service life? “In smaller laboratories, such questions can only be answered to a limited extent,” says Johannes Adler. “But it was not possible to subject power electronic components from wind turbines to extreme load tests on a full scale before the test laboratory was built. This facility is unique in Europe.”

© Hajo König

In the HiPE-WiND research project, for which the test stands were a prerequisite, the IALB worked closely with the Fraunhofer Institute for Wind Energy Systems (IWES) in Bremerhaven and three partners from industry. The focus was on wind energy. Power electronics are a key component of wind turbines, as they “control” the power flow of the turbine.

“It is subject to a great deal of stress,” explains Holger Raffel from the Bremen Center for Mechatronics, with which the IALB has joined forces alongside three other university institutes. “The loads come from several sides – the constantly fluctuating wind and the loads from the grid, for example. Wind may blow weakly or stormily and may change rapidly; grid loads are caused by voltage or current surges due to switching actions, short circuits, or lightning strikes. In addition, there are a wide range of environmental influences: large temperature jumps, highly fluctuating humidity and even condensation, interactions between the different mechatronic powertrain systems, and much more.” Experts call such diverse loads “multimodal.”

„Without a doubt, this laboratory impresses me every day and is one of the largest at the University of Bremen.“ Wilfried Holzke, IALB

The wind turbine must be prepared for all these changing influences, especially on the high seas. It has to operate simply, because an outage results in very high costs and a lot of work. “A high level of reliability is more important for offshore turbines than on land,” says Holzke. “When it comes to repairs or maintenance, you simply can’t get there that quickly.”

In the HiPE-LAB, it is now possible to carry out load tests on turbine parts at full scale. The focus here is on power electronics – specifically the frequency inverters. Holger Raffel explains what this is: “Frequency inverters change the alternating voltage generated by the wind turbine’s generators in such a way that it can be used to feed the grid. The electricity generated must be ‘recyclable and fed into the grid’ for various purposes, making it usable for consumers.” For Raffel, the frequency inverters are the heart of a wind turbine: “This is a key component. It pulsates, it pumps, it supplies, it keeps everything that is built around it alive.” The HiPE-LAB is an ideal prerequisite for new research on green transformation at the University of Bremen.

Exposures over 20 Years Can Be Simulated

This is the reason why the frequency inverter in particular has to operate smoothly. In the HiPE-LAB, it is not only exposed to the various loads for short periods, but also in a long-term simulation. “In multi-shift operation, we can run programs over extended periods of time that simulate the stresses on the wind turbine components that they will have to withstand in up to 20 years,” says Holzke. Similar to this large-scale electronic IALB test rig, Fraunhofer IWES, a research partner in Bremerhaven, offers similar possibilities for putting original parts under load, such as nacelles and rotor blades.

© Kai Uwe Bohn / Universität Bremen

The hall in Bremen impresses with its spacious climate chamber, into which control cabinets weighing up to 10,000 kg can be pushed with inverters “to stress them.” There are also smaller climate chambers for examining power semiconductors, driver circuits, or intermediate circuit capacitors, as well as comprehensive electrotechnical equipment on two floors. A total of around 6 km of cables were laid and more than 100 switch cabinets installed in which the inverter technology, control technology, and other auxiliary components for the test bench are installed.

“The load system simulates both the behavior of a wind turbine generator with frequencies from 0 to 70 Hz and the power grid. In order to have flexibility when providing the required performance bandwidth of ‘test objects,’ the system was constructed from four similar units, each with an output of 2.5 MW,” explains Holzke. Parallel connection means that the component to be tested can be electrically loaded with up to 10 MW. “To achieve this, the grid-side inverters and the generator-side inverters each have to work in sync, which is a challenge,” says Holzke.

Companies: “We May Not Come Right Away – But We Will Come”

The extensive installations ultimately make it clear why this laboratory has spent several million euros. In order to make the most of it, industrial customers are also being acquired in addition to university research. “For example, we gave a presentation at the European Conference on Power Electronics and Applications in Hannover in early September 2022,” says Holzke. “The response was very positive. Many companies have said to us that we have something great. We may not come right away – but we will come.”

© Hajo König

The research laboratory is interesting not only for the wind energy industry, but also for the photovoltaics and mining sectors, for example. “Ultimately, machines also run under conditions that stress them a lot – or even in the mountains,” says Holzke. He and his colleague Johannes Adler support industry in climate tests with conditions ranging “from the Arctic to the Sahara” – especially since stable green energy generation requires reliable power electronics to ensure we all have a stable power supply in the future.

Further information can be found on the website of HiPE-LAB.