© cellumation GmbH

Startup Cellumation: The Lego Blocks of Conveyor Technology

Successful startup company from the university: The BIBA spin-off company cellumation GmbH has developed an entirely new conveyor system

Impress the right people at the right time with the right idea and success is guaranteed? It’s unfortunately not that simple for a spin-off company from the scientific sector. The young Bremen company cellumation GmbH, a startup company from the Bremen Institute for Production and Logistics GmbH (BIBA), has done exactly that. In the logistics sector, their conveyor development – the celluveyor – is an innovation that has woken a great deal of interest.

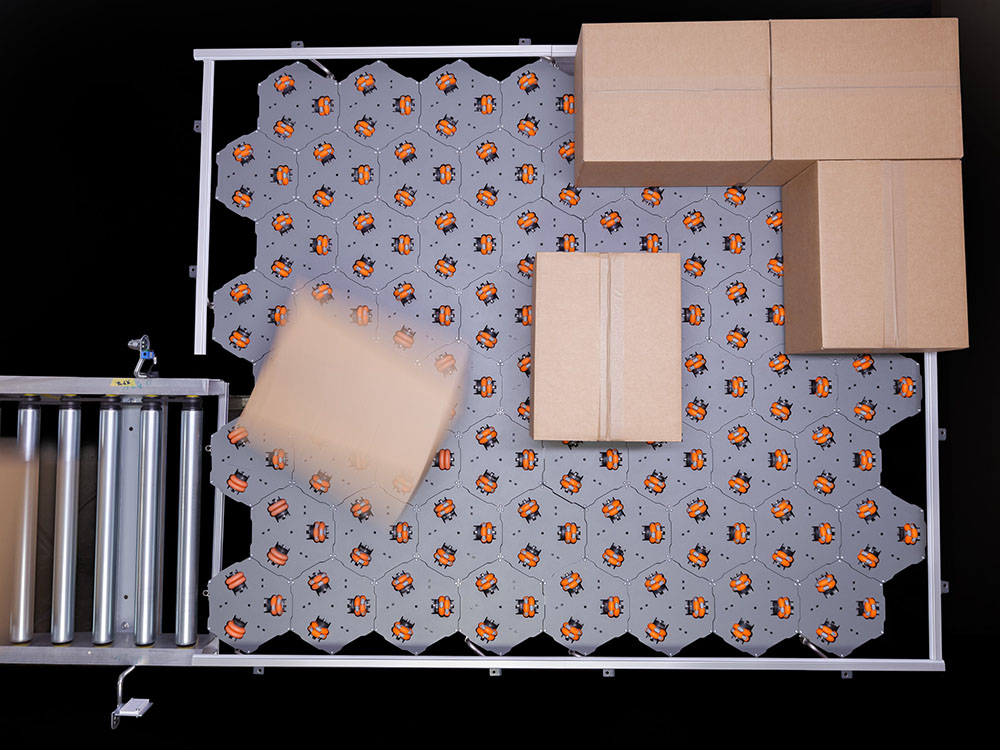

Omnidirectional and hexagonal. Both of these words play a central role when you want to try and clearly explain the celluveyor invention from the Bremen startup cellumation GmbH. The placing of the wheels allows for omnidirectional movement of the transport system. And hexagonal means it has six sides. That is how the individual system cells are formed. They can then be combined with other cells to create the desired conveyor belt.

Click – click – click: It’s as simple as that if you want to connect the modules. “That is why we also speak of the Lego blocks of conveyor technology,” grins Dr.-Ing. Hendrik Thamer, managing director of cellumation GmbH, which was founded in 2017. Highly flexible, space-saving, and innovative: Some press releases regarding the celluveyor call it a “revolution.”

© cellumation

The invention from Bremen fits into a world where there has been a boom in logistics. Due to the number of rapidly increasing online orders – that have been additionally driven by the corona pandemic – one can nearly speak of a tsunami with regards to parcel logistics. “Many people are aware of the photos taken in large halls where long conveyor belts with packages run. That works quite well in a straight line but there are jams when the direction is changed, at nodal points, or crossroads,” says Hendrik Thamer.

Inventor Spirit from BIBA

It is a little odd: Logistics research into packing robots and parcel delivery by drones has been carried out, “but not a great deal has changed since 1900 for conveyor technology.” But thanks to the inventor’s spirit at BIBA, where intelligent production and logistics systems have been investigated since 1981, it’s happening now.

That is where Hendrik Thamer and Claudio Uriarte met. After his computer science degree in Oldenburg, Thamer took a job as a scientific assistant at BIBA and completed doctoral studies in the field of artificial intelligence in logistics automation at the same time. In 2014, he took on the role of the head of the department for robotics and automation at the institute. Uriarte studied machine engineering in Chile, qualified as a design and patent engineer, has been the leader of many development projects since 2009, and laid the foundation for many technical innovations at BIBA with his innovation spirit.

© cellumation GmbH

Together with colleagues, they expanded on one of Claudio Uriarte’s ideas in 2012: He was to develop a highly flexible conveyor surface that could be moved in all directions as part of a research project. “However, there was no suitable technology on the market,” remembers Uriarte today. “That’s why nothing became of the project.”

Several months later, the man who is now cellumation’s Chief Technical Officer (CTO) watched a few robots play football. “The football robots moved freely in all directions without difficulty. That’s when I thought: If we turn them on their heads, packages and other objects with a flat bottom surface must surely be able to transported perfectly on the wheels!” he reminisces.

Year Long Work on Product Development

The idea had been born but as we all know, our minds are quicker than our hands. “Creating and designing an invention, then further developing it and making it patent ready, building hardware and programming software – that means years of hard work,” underscore Thamer and Uriarte. And you need support from the other side: From the institute, from startup sponsors, from consultation services. The cellumation directors, who emphasize the support received from BIBA, the InnoWi Patent Center, the UniTransfer office, state services, Bremen startup networks, and many more, had all of that.

Both of the cellumation bosses worked on the celluveyor with other dedicated colleagues for nearly six years. “At BIBA, we had great freedom and were able to try out a lot in order to develop the system. But we often had to do the work during the night and at the weekend, as we primarily had to do our actual jobs,” according to Thamer. The prototypes of the novel conveyor system were initially made from remaining materials and replacement parts. One of them is still hanging on the wall of the cellumation GmbH meeting room.

Simply Clicking Together Desired Transport Paths

The core of the celluveyor is formed by the hexagonal cells with three wheels that can be individually controlled. The cells can simply be “clicked together” on each of the six sides – much like Lego blocks. This means that the conveyor system can be put together as one desires and can be adapted to the space and the differing tasks depending on material flow. “Regardless of which transport path is created: The hardware always remain the same – independently of the application,” says Claudio Uriarte. “The controlling of the cells is only carried out by means of the software. An intuitive, graphic user interface makes it possible for the users to complete the programming without having to have prior special knowledge.”

© cellumation GmbH

Those who can work a tablet or cell phone can also use the system. Simple construction, easy set-up, uncomplicated usage, and it’s space saving: That’s the sort of thing that does well in the logistics industry.

Those who can work a tablet or cell phone can also use the system.

The logistics experts received time and money for the development up until the product was ready and until their own company was established from the two-step EXIST Research Transfer Program from the Federal Ministry of Education and Research (BMBF). The program is specially designed for university and non-university research institutes. In May 2017, the company was founded as the final act of phase one. Afterwards, actually starting the business and findings investors were the next job.

Sponsors for Growth Path

“We wanted to enter into batch production with our product but first needed to produce innumerable cells ourselves and find our first customers – and of course sponsors who believed in us and with whom we were able to begin our growth path,” remembers Hendrik Thamer. Cellumation GmbH took its first steps at BIBA and then at the beginning of 2019, the company moved into their own space in the Technology Park. The move entailed an office, a hall, a small workshop, and a total of six people.

Today, nearly two years later, the number of company members has increased eightfold and cellumation is looking for more space and more staff. “We are very proud of what we have achieved to date – and we have big plans,” is how Hendrik Thamer summarizes the first two years of self-employment. The celluveyor is actually fulfilling many expectation that the logistics industry has with regard to a modern conveyor system.

“We are very proud of what we have achieved to date – and we have big plans.”

Thanks to “system integrators” – service providers that buy new technical innovations for logistics companies and set them up technically in the logistical centers – cellumation has business with the parcel service provider DHL and the print and industrial corporation Arvato Bertelsmann Supply Chain Solutions. The Spanish company Vector Conveyors has come on board as an investor. They have brought a great deal of expertise from the fields of production and industrial requirements to cellumation GmbH and are now batch producing the celluveyor cells.

Highlight: Spanish TV Show

It is not least down to this partner that the celluveyor has already made it onto Spanish prime time TV. In February 2020, the invention from Bremen was one of the highlights of the very popular TV show “El Hormiguero,” which is all about science, culture, comedy, and politics. “At absolute prime time, we were able to show an amazed audience how the celluveyor brought together a chaos of square parts to form a film poster by means of rapid turn and push maneuvers.” With these connections to South Europe, it is a given at cellumation that not only the Chilean Claudia Uriarte speaks fluent Spanish, but that Hendrik Thamer now does too.