© Matej Meza / Universität Bremen

Have You Heard of... the Carpentry Workshop?

There is a lot to be discovered on campus. What’s behind all those doors? up2date. knocks on some of them to find out. Welcome to a slightly different tour of the campus!

Despite being concealed by two thick, fire-proof doors, you can guess what is behind them as soon as you enter the long corridor of University of Bremen’s maintenance depot. The warm and earthy smell of wood gives it away. Amongst wood shavings, boards, and drawing plans, the carpentry workshop is the place for drilling, repairing, and sawing. This is master carpenter Christiane Sarnow’s realm, with her two journeypersons and four trainees. She has been at the University of Bremen since 2005 and heads the carpentry workshop. Above all, she focuses on one thing: providing the next generation with a good education.

The saws, planers, and mallets are ready in a large room with a bright window front. Carpenters and carpenters in training work on various orders from the university at their workbenches as well as in the adjacent machine room. Sarah is currently busy with one of these assignments – more precisely, with a kitchen for the GEO building. She is a second-year apprentice in the workshop and is currently working on a countertop for the custom-made kitchen. “The room is very tubular; the kitchen is to go around the corner. Therefore, the challenge was to use the space as best as possible,” explains the 26-year-old. Master carpenter Christiane Sarnow adds: “We have a lot of special requests. We not only repair doors, windows, and furniture and carry out wood technology work on reconstruction projects, but also create custom-made products.” University employees can write a ticket to the building management with their project request. If the request is suitable for customization, they take measurements, discuss wishes, present designs, and implement and install the finished project. Trainees take over this task from the second year of apprenticeship, as soon as they have completed their machinery certificate. In the apprenticeship, it is especially important to the master carpenter that the apprentices work through all the steps themselves and do not just watch the journeypersons or give them tools. “To provide this training, I sometimes ‘chase’ orders for custom-made items such as kitchens, display cases, built-in cabinets, and office furniture. They learn more through these more demanding tasks, than by doing finishing touches or repairs,” explains Christiane Sarnow.

© Privat

Practicing Handwriting

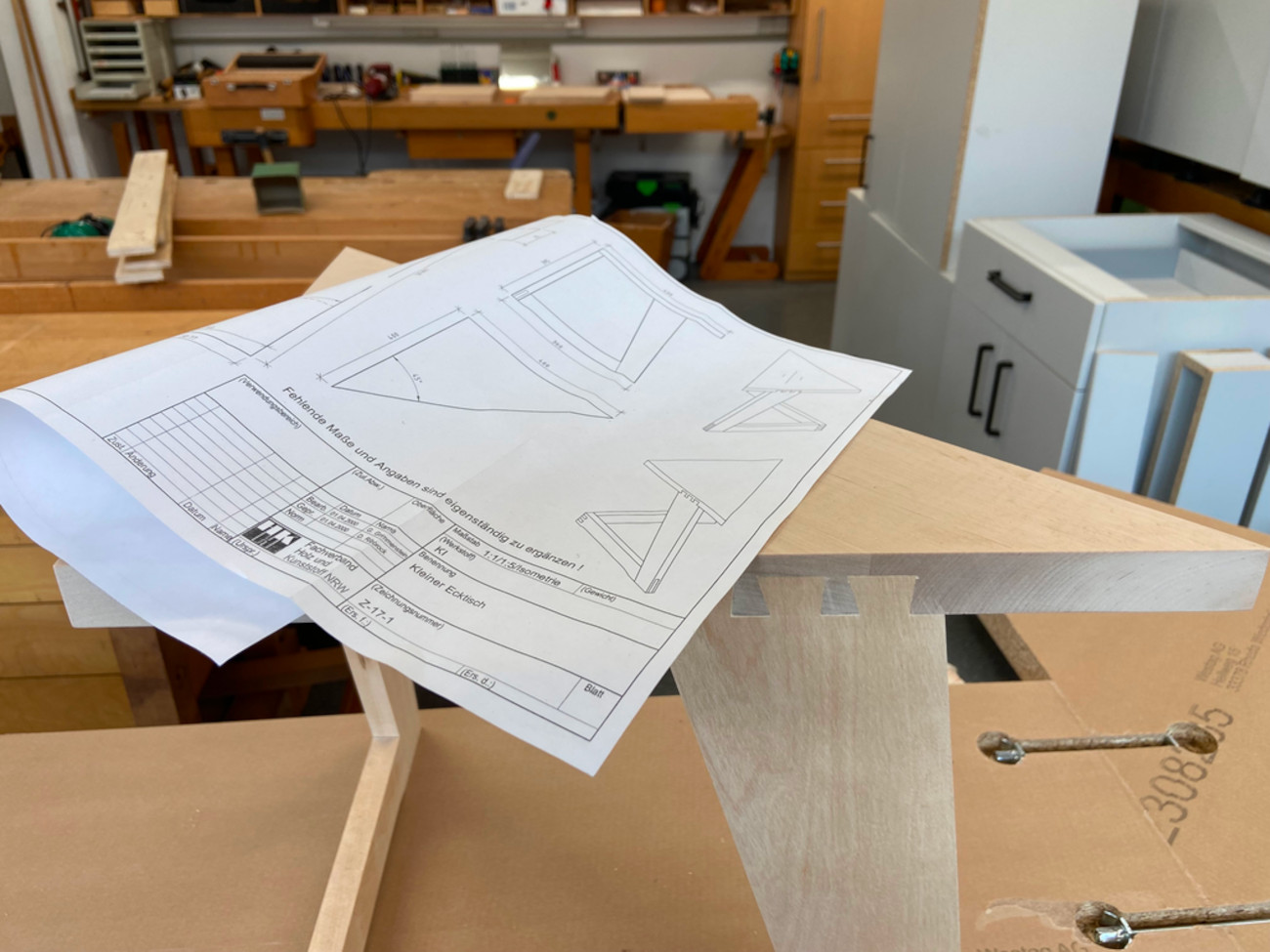

Creating an entire kitchen may not be possible in the first year of apprenticeship, but even then the apprentices are already actively involved, Sarah says. “A lot of work is done by hand in the first year, because you first have to understand what you are doing. In the school part of our training, we learn the theory behind things, such as how to read woodworking plans. The workshop is where we implement it.” She has practiced using classic wooden joints by building a corner table, she explains. In a thick folder with different training pieces, the trainees can choose what they want to build in order to practice reading plans and making objects to scale. “This craftsmanship is very important to me. It is how the apprentices develop their own handwriting, which later becomes their trademark – almost like a typeface,” Christiane Sarnow explains when describing her curriculum.

© Universität Bremen

“I wanted to educate and I wanted to do it better.” Christiane Sarnow

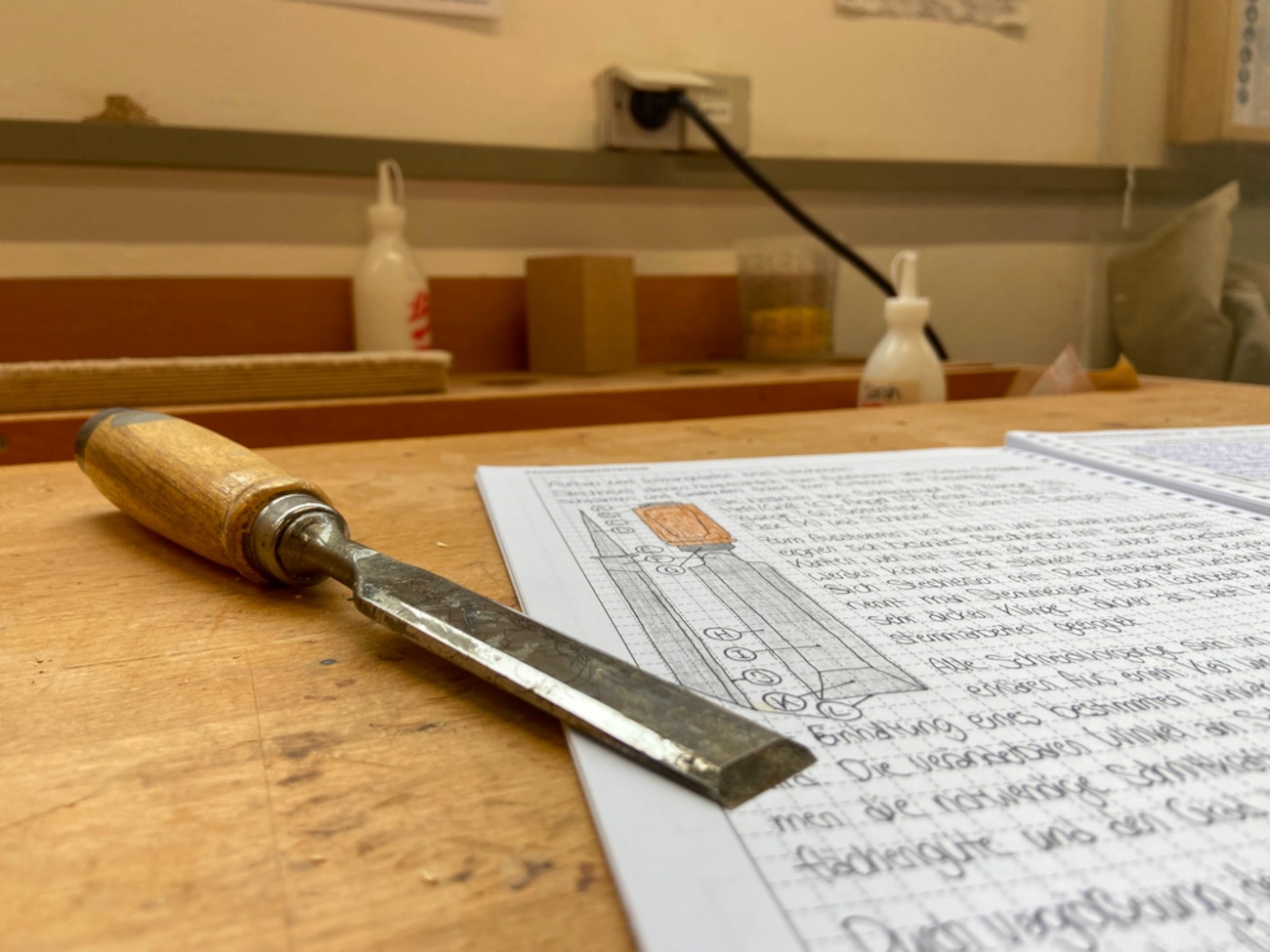

It’s easy to see that the master carpenter highly values her apprentices – not just because she trusts them a lot and lets them do a great deal, but also by the fact that she knows their strengths well and appreciates these. “Sarah is not only very accurate at carpentry, but also writes beautiful and detailed reports for the vocational school, which she enhances with great drawings.” Since 2005, Christiane Sarnow has headed the Wood Technology Workshop, as the carpentry workshop at the University of Bremen is officially called. Her desire to not just be a carpenter, but train other carpenters was made evident by a certain event. “I once observed a journeyperson standing on a ladder. His apprentice stood at the bottom and only woke up from his boredom when he was supposed to hand the journeyperson a tool. However, the trainee below could not see what was being worked on up there.” After that, Christiane Sarnow completed her master training at evening school with one goal: “I wanted to educate and I wanted to do it better.”

© Universität Bremen

Exam Preparations

Next to Sarah’s workbench, Jarnis is planning his journeyperson piece. He is in his third year of the apprenticeship. While the journeyperson’s piece must be produced as a final project of his training within a fixed examination period of 100 working hours in June, he now has time to test whether his planning will succeed. That is why he is already thinking carefully about the construction style and the type of wood for the sideboard. It’s important to him that his work has a certain degree of difficulty: “Since we don’t have a CNC machine with which I could mill the front of the sideboard, I have to do it by hand. This is elaborate, but I want it to look modern and timeless and be proud of the finished product.” He has already decided that the type of wood should be cherry. The wood is not very porous, which is why it is optimal for his purpose. In addition, it is sustainable, as it comes from Europe. Surely, he will get bonus points in the exam for that, he grins. He recently built a model for MARUM – Center for Marine Environmental Sciences, which was his most challenging training project, he says with a smile. “In the end, the most annoying project turned out to be the most rewarding.”

Popular Vocational Training Location

So far, the university carpentry workshop has not been affected by the usual lack of apprentices in the handcraft sector. On average, 54 good candidates apply for each apprenticeship, says Christiane Sarnow. Jarnis is satisfied with his training in carpentry at the university: “Everyone does everything here. We are assigned our projects according to our abilities and development opportunities. I feel well prepared for starting a job.” When asked why the university’s carpentry training is so sought after, the master is sure: “We are a popular employer because word gets around that we support our trainees and don’t leave them hanging.”